Clean water is the foundation of healthy communities, thriving economies, and a protected environment. Water and wastewater treatment systems are critical to deliver safe drinking water, preventing disease, supporting industries, and safeguarding our natural resources.

At Graham, we understand that delivering these vital infrastructure projects takes more than engineering—it takes vision, precision, and a proven track record. From new plant construction to major upgrades, we’ve successfully managed some of the most complex water and wastewater treatment projects across North America. Our integrated approach combines detailed planning, innovative thinking, and a deep understanding of operational needs to keep projects on time, on budget, and built for long-term performance.

“Our skilled teams are carefully assembled to combine technical expertise with practical operational experience,” says Jeremy Klarenbach, Vice President, Operations. “We bring together professionals who not only know how to build but who also understand the bigger picture—how every decision impacts operations and communities for years to come.”

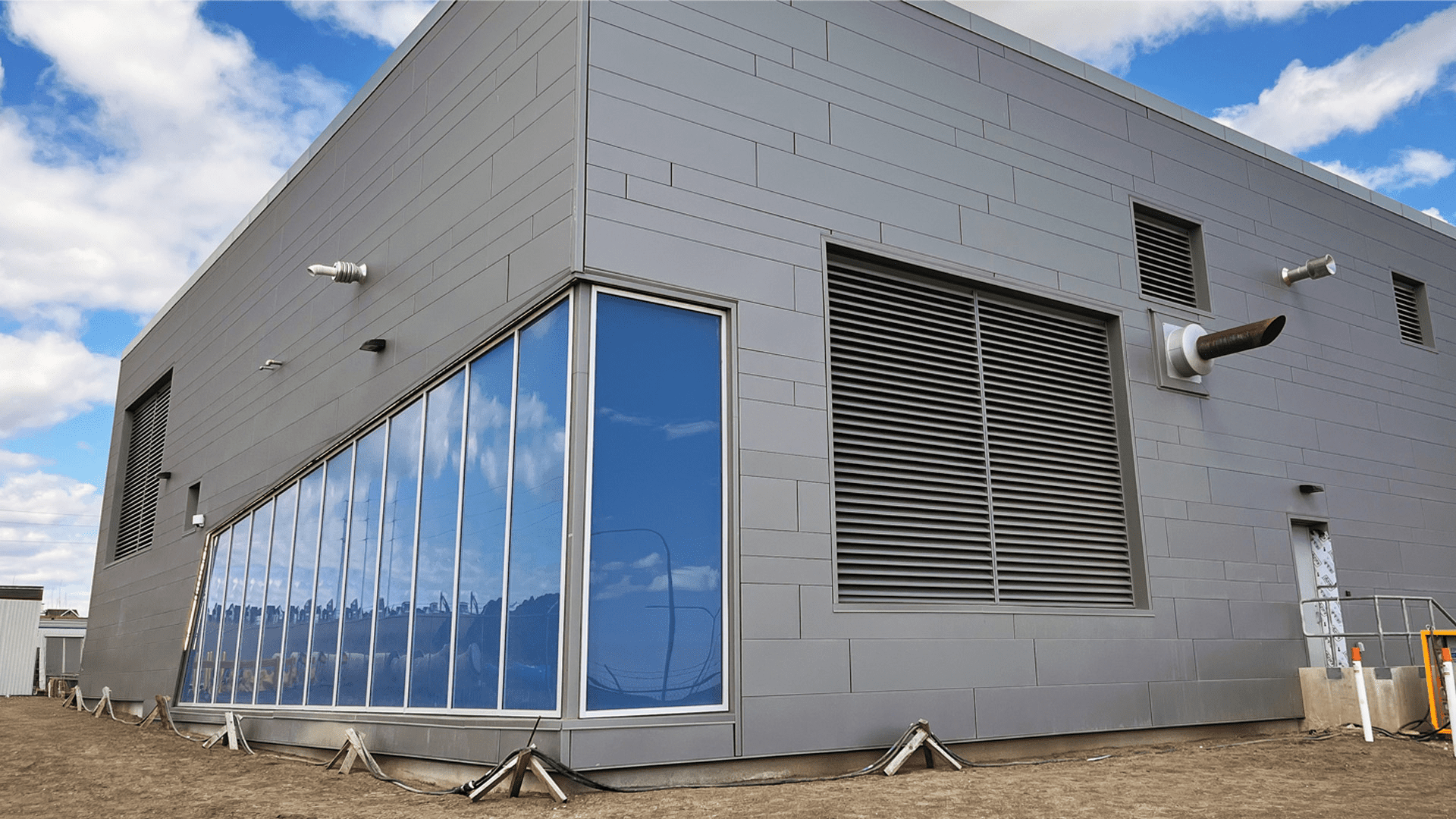

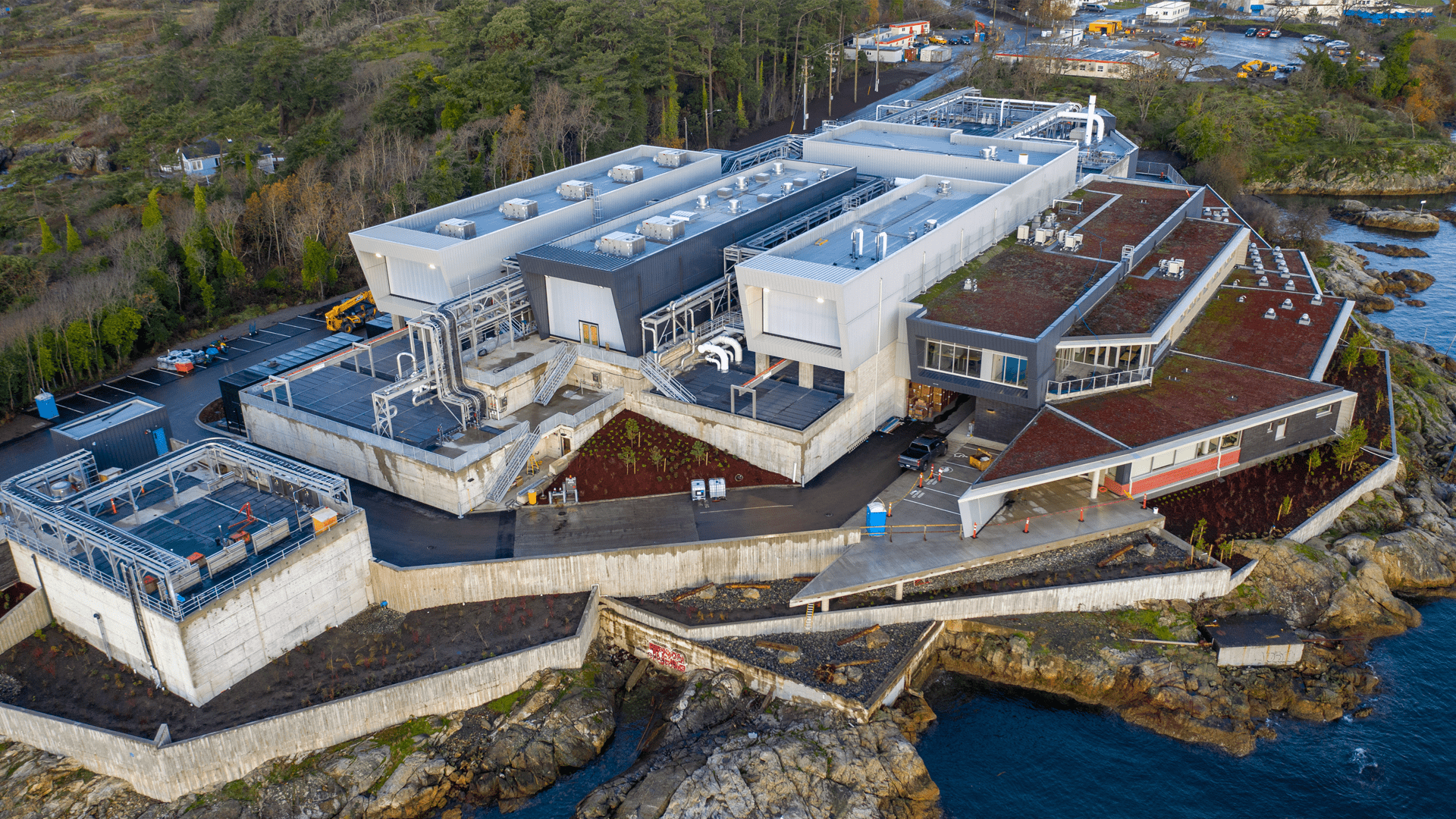

McLoughlin Point WWTP, LEED Gold Certified (Victoria, BC)

Early Planning is Critical

Under an Early Contractor Involvement (ECI) delivery model, Graham identifies and addresses potential issues before they impact the schedule or budget.

“Getting involved early allows us to anticipate and solve problems well before they become costly roadblocks,” explains Tyler Krug-Wilson, Operations Director. “When we proactively identify risks, we significantly improve project outcomes and predictability.”

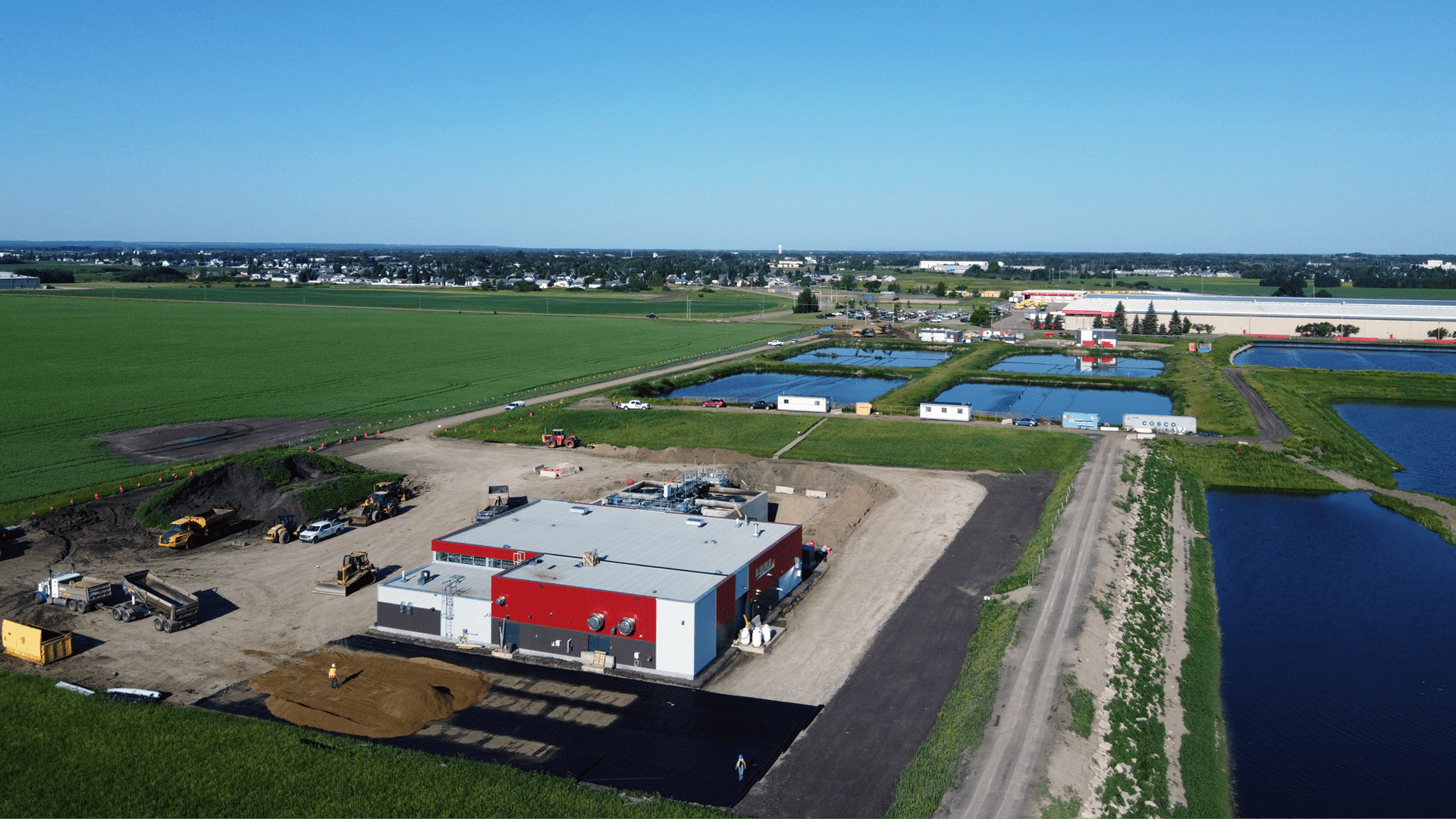

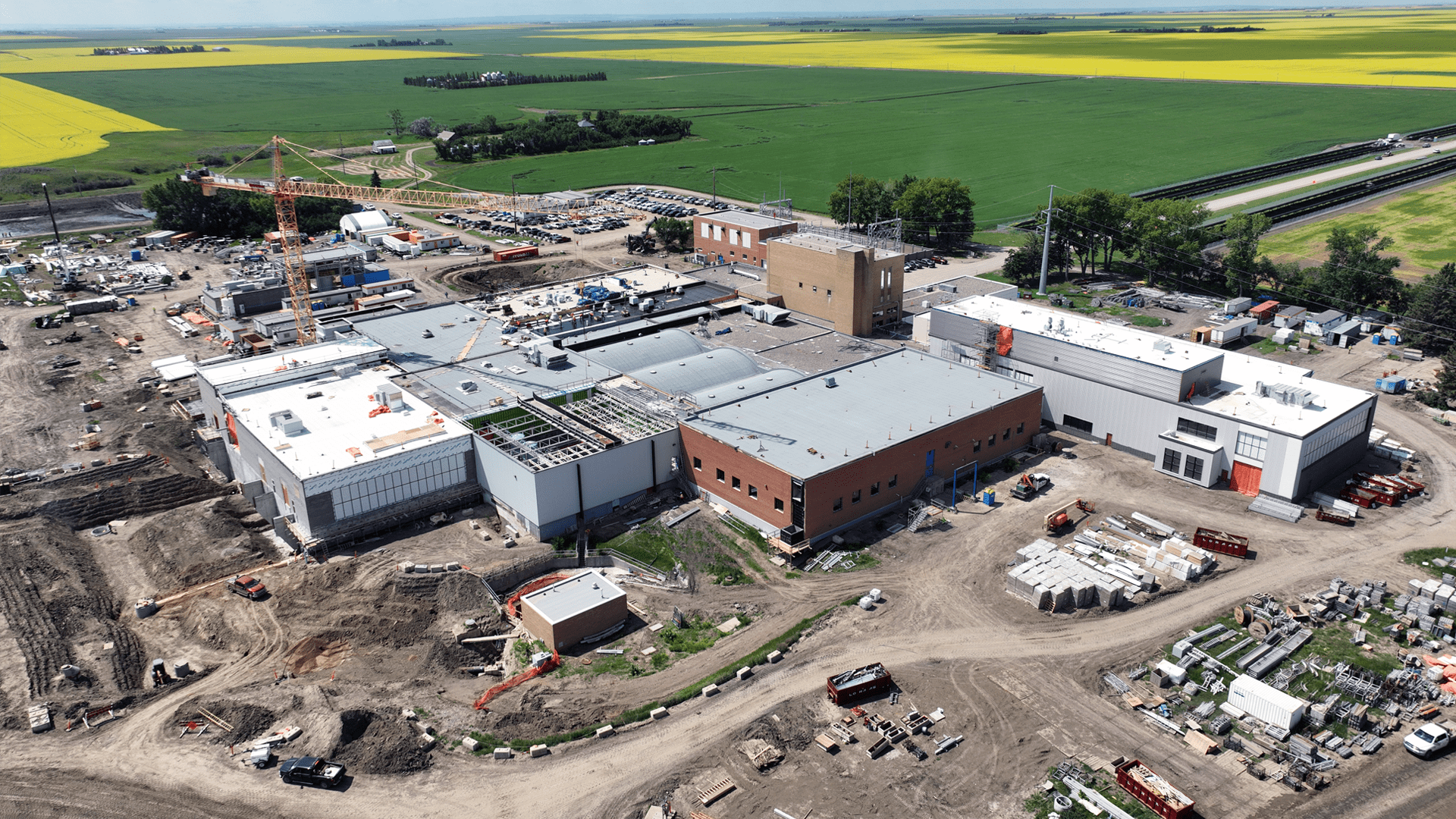

Graham’s expertise encompasses a diverse range of project delivery models—CMAR, IPD, Progressive Design-Build, CM/GC, and P3—allowing the team to tailor strategies that best meet client objectives. This versatility has been demonstrated on high-profile projects like the Buffalo Pound WTP (Canada’s first Progressive Design-Build project), Bonnybrook WWTP, Fish Creek WWTP and Regina WWTP.

“Adapting our delivery approach to suit each project’s unique requirements is central to managing complexity,” says Klarenbach. “Our proven methods ensure alignment between client needs and project execution, ensuring both efficiency and success.”

Integrating Digital Technology

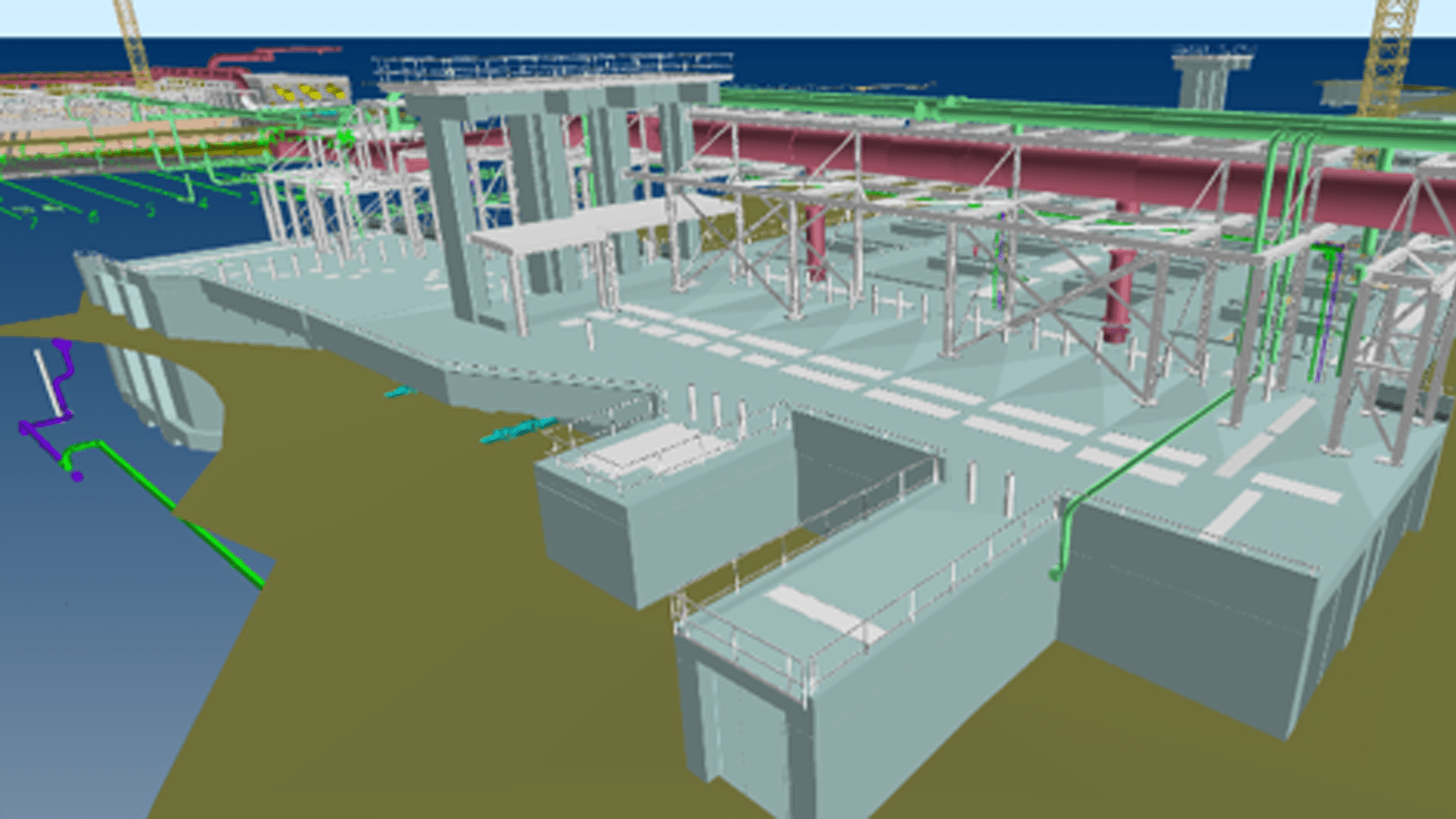

Leveraging advanced digital tools significantly enhances Graham’s ability to manage complexity effectively. Technologies like OpenSpace, DroneDeploy, cmBuilder, and Propeller Aero offer precise virtual site visualization and real-time progress tracking. LiDAR scanning and detailed 3D modeling provide greater accuracy in planning, especially valuable for intricate brownfield projects.

“These digital tools allow us to identify potential conflicts long before they become real issues on-site,” explains Iain Kirk, Operations Director. “At facilities like Bonnybrook WWTP in Calgary and EL Smith in Edmonton, we’ve used these technologies to anticipate operational conflicts early, minimizing disruptions during construction.”

BIM (Building Information Modeling) – Annacis Island WWTP (Delta, BC)

Coordinated Execution in Live Operational Environments

Delivering water and wastewater infrastructure upgrades within active facilities requires more than construction expertise—it demands strategic planning, seamless coordination, and meticulous execution. At Graham, we specialize in performing complex work without interrupting ongoing plant operations.

Our teams work closely with plant operators to plan every detail—from sequencing and staging to scheduling shutdowns. We use advanced 3D modeling to develop comprehensive staging and sequencing plans, enabling work in multiple areas simultaneously while maintaining plant functionality. Critical upgrades, including tie-ins, isolations, and bypass pumping, are carefully managed through robust temporary works and enabling works standards.

Collaboration is key. We conduct risk workshops, joint reviews, and frequent progress meetings to align with operational needs. Planned shutdowns are coordinated during off-peak hours and guided by detailed schedules, rigorous Lock-Out-Tag-Out procedures, and structured return-to-service protocols—ensuring minimal downtime and maximum reliability.

“We take a proactive approach to risk management,” says Kirk. “Every action is planned well in advance, and detailed safety protocols are in place long before boots hit the ground.”

Innovation to Overcome Technical Challenges

Complex challenges require innovative solutions. A prime example is Graham’s work on the Annacis Island WWTP, where the team engineered a groundbreaking flume system constructed from double-stacked shipping containers to manage high-volume wastewater flow during a critical structural tie-in. This approach mitigated operational risks and significantly reduced costs. The knowledge gained here directly influenced the Gold Bar WWTP project in Edmonton, eliminating the need for costly bypass pumping and saving over CDN $4.0 million.

Double-stacked Shipping Containers Channel Bypass – Annacis Island WWTP (Delta, BC)

“Our innovation doesn’t just solve immediate problems; it often sets new standards for future projects,” notes Byron Chamberlain, Construction Manager. “We’re always looking for smarter, safer ways to execute work, reducing both risk and expense.”

Channel Bypass – Gold Bar WWTP (Edmonton, AB)

Self-Performing to Ensure Quality and Control

A key component of Graham’s ability to manage complex projects is its capability to self-perform up to 60% of project scopes, including civil, mechanical, structural, and process commissioning work. This approach provides greater control over execution, quality, and scheduling, resulting in fewer risks and higher project predictability.

“Being able to perform a large portion of the work ourselves gives us direct oversight of quality,” notes Krug-Wilson. “It allows us to rapidly respond to challenges, maintain schedules, and consistently deliver high-quality outcomes.”

A Proven Approach

By emphasizing thorough planning, digital innovation, careful execution, and robust self-performance capabilities, Graham effectively manages complexity in water and wastewater infrastructure projects—delivering more than $300 million in projects annually. As communities grow and facilities age, navigating these challenges successfully will remain critical—and Graham’s proven, innovative approach ensures that communities continue to operate sustainably and reliably.

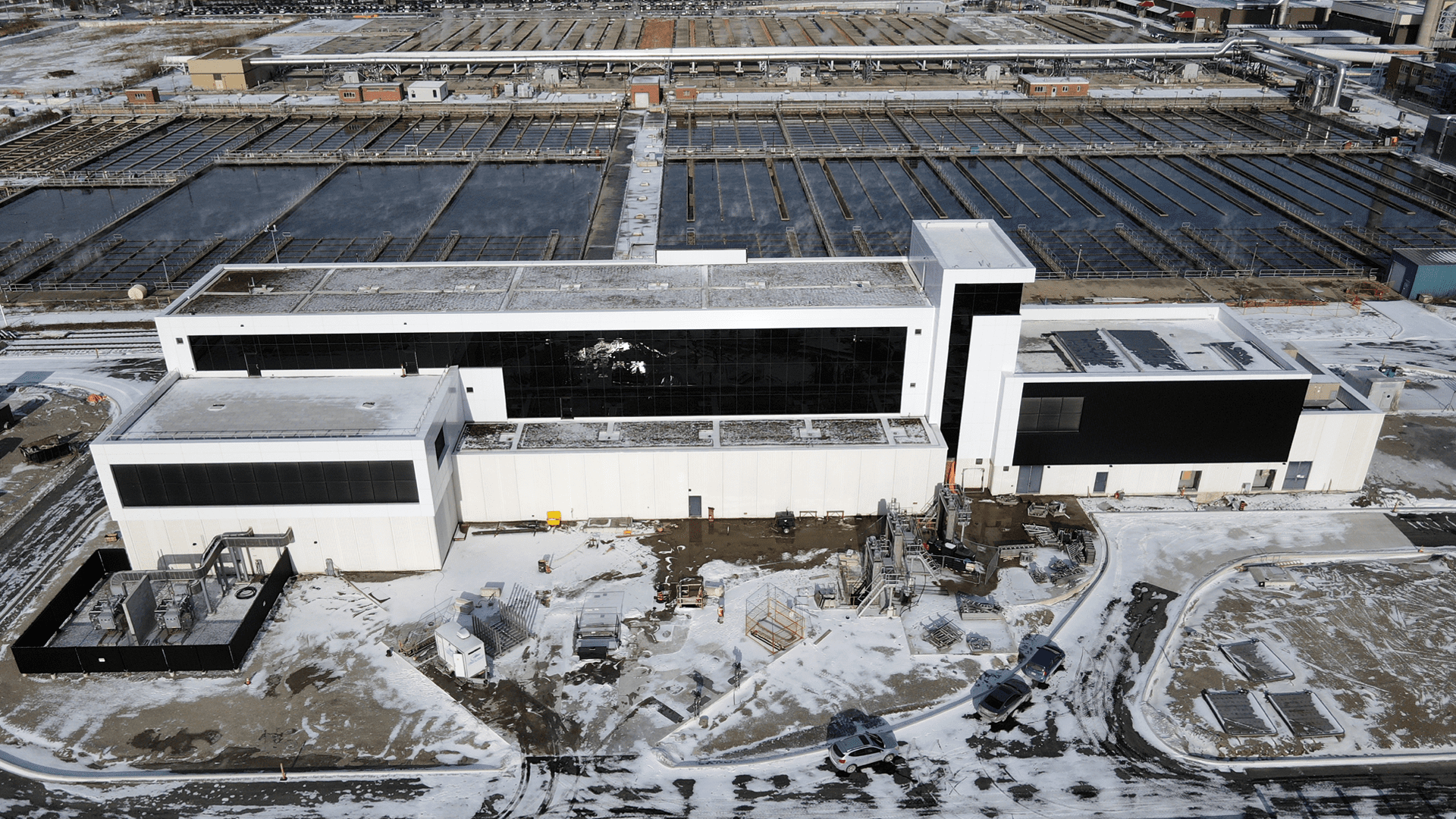

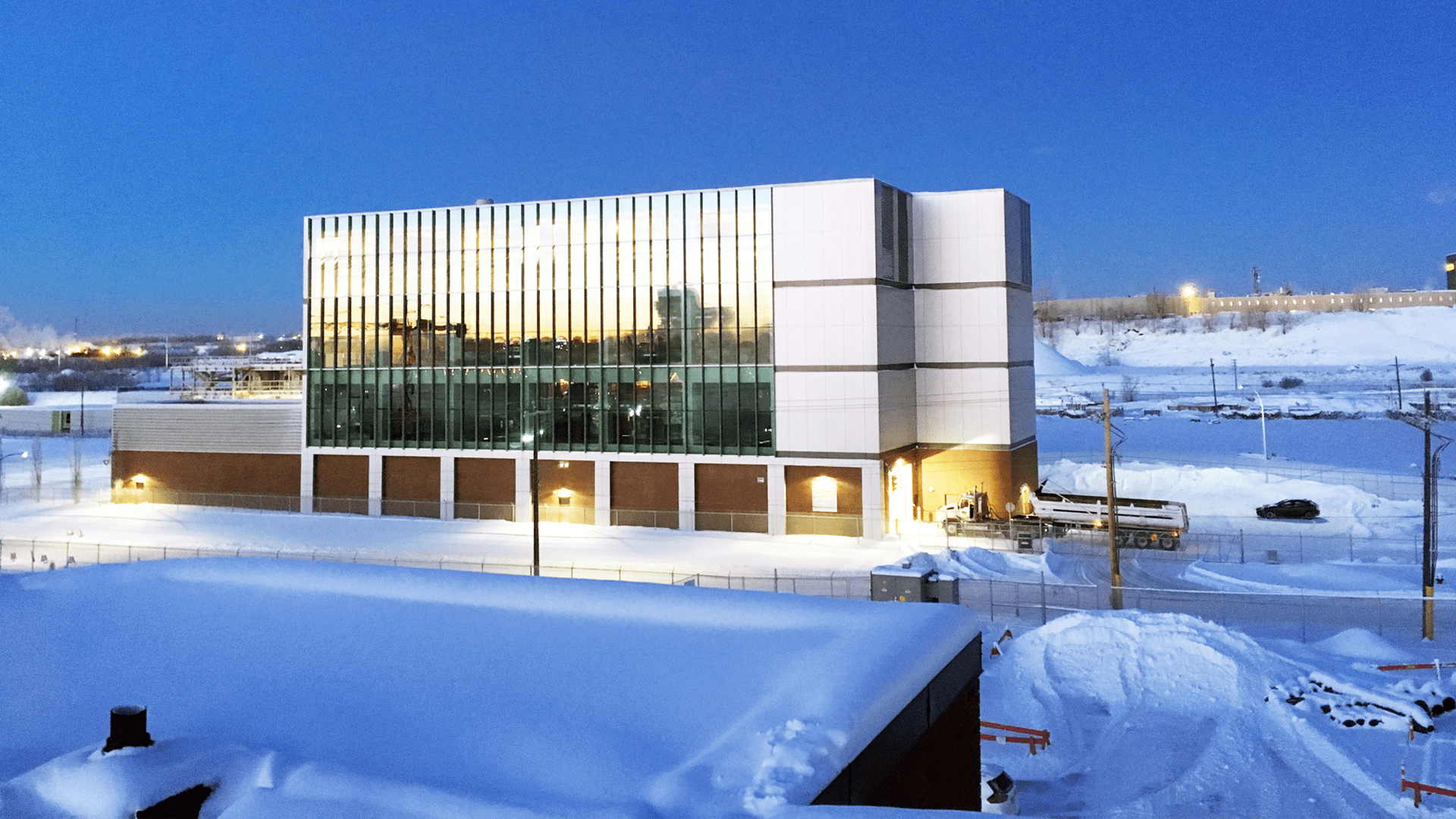

Bonnybrook WWTP – Largest cold-weather biological nutrient removal (BNR) plant in the world (Calgary, AB)